Creating your own diy ping pong table can be a rewarding and cost-effective project that lets you enjoy this fun and competitive game at home. With the right materials and tools, you can design a table that meets standard dimensions or customize it to fit your available space.

This guide will walk you through the necessary steps of how to make a ping pong table, functional ping pong table while sharing tips for achieving the best playing surface. Whether you’re a seasoned DIY enthusiast or a beginner looking for a creative project, this is a great way to add entertainment to your space.

The Benefits of Making Your Own Ping Pong Table

Building your own ping pong table comes with several advantages that make it a worthwhile project. First and foremost, it allows you to save money compared to purchasing a pre-made table, especially high-quality models that can be quite expensive. Additionally, you have the freedom to customize the size, materials, and design to perfectly suit your needs and the space available in your home or outdoor area. This can be particularly beneficial for smaller spaces where a standard table might not fit.

Furthermore, the process of constructing the table gives you a sense of accomplishment and an opportunity to sharpen your DIY skills. Finally, creating a custom ping pong table can add a personal touch to your recreational setup, making your space feel more unique and tailored to your lifestyle. The memories of crafting it can also enhance the enjoyment of every game played on it.

Tools and Materials You’ll Need

To successfully build your own ping pong table, you’ll need to gather the appropriate tools and materials before starting the project. Here’s a list to help you get started:

Tools:

- Measuring Tape – To ensure accurate dimensions for the table.

- Circular Saw or Hand Saw – For cutting wood to the required sizes.

- Power Drill and Drill Bits – To assemble the table frame and attach hinges or brackets.

- Screwdriver – For securing screws during the assembly process.

- Level – To make sure the table surface is perfectly flat and balanced.

- Sandpaper or an Electric Sander – To smooth the surface of the table for optimal gameplay.

- Paintbrush or Roller – For applying paint or sealant to the table.

- Clamps – To hold materials in place while cutting or assembling.

Materials:

- Plywood Sheet – This will act as the playing surface of the table. Standard tables are made of MDF or similar materials for a smooth finish.

- Wood for the Frame – Sturdy hardwood or dimensional lumber to build the table’s frame and legs.

- Wood Screws and Nails – For attaching the parts together.

- Wood Glue – To provide additional stability to the structure.

- Paint or Tabletop Coating – Use green or blue paint with white lines to mimic the appearance of professional ping pong tables.

- Net and Post Set – To create the net system for gameplay.

- Adjustable Table Feet (optional) – These can help balance the table on uneven surfaces.

Having these tools and materials ready will streamline the building process, ensuring you can assemble your custom ping pong table efficiently and effectively.

10 Methods How to Make a Ping Pong Table

1. Using a Plywood Sheet with a Sturdy Frame

One of the simplest ways to make a ping pong table is by using a high-quality plywood sheet for the playing surface. A standard ping pong table measures 9 feet by 5 feet, so you’ll need a plywood sheet of similar dimensions. Attach the sheet to a sturdy wooden frame using screws and brackets to ensure stability. Sand the surface thoroughly and apply a coat of paint or varnish to enhance durability and create a smooth playing surface.

2. Building a Foldable Ping Pong Table

For those who need a space-saving solution, constructing a foldable ping pong table is ideal. Use two separate plywood sheets, each measuring 4.5 feet by 5 feet, and hinge them together at the center. This allows the table to fold for easy storage. Add collapsible legs or attach the surface to a sturdy foldable table frame. Installing locking mechanisms will ensure the table remains stable during gameplay.

3. Converting an Existing Table

If you have a large, sturdy table such as a dining table or workbench, you can repurpose it into a ping pong table. Attach a removable plywood top cut to the appropriate size. Use clamps or brackets to keep the surface in place during play. For added convenience, paint boundary lines and attach a portable net to complete the setup.

4. Using MDF for a Smooth Playing Surface

Medium Density Fiberboard (MDF) is an excellent alternative to plywood as it provides a smoother and more uniform playing surface. Cut the MDF board to the correct dimensions and reinforce it with a wooden frame underneath to prevent warping. Use a high-quality primer and multiple layers of polyurethane paint to create a durable and scratch-resistant surface.

5. Constructing a Concrete Ping Pong Table for Outdoor Use

For those looking to build a permanent and weather-resistant ping pong table, using concrete is an excellent option. Construct a mold with wooden planks and pour a concrete mixture to create a thick, sturdy tabletop. Once cured, sand the surface and apply an outdoor-friendly paint. Pair it with a durable metal frame and legs to ensure longevity. This type of table is perfect for parks or backyard setups.

6. Using a Glass or Acrylic Surface

For a unique and modern take on a ping pong table, consider using a tempered glass or acrylic sheet for the playing surface. These materials provide a sleek look and a distinct bounce characteristic. To prevent shattering or breakage, use at least 1/4-inch thick glass and reinforce the edges with rubber padding. A metal or wooden frame can provide the necessary support.

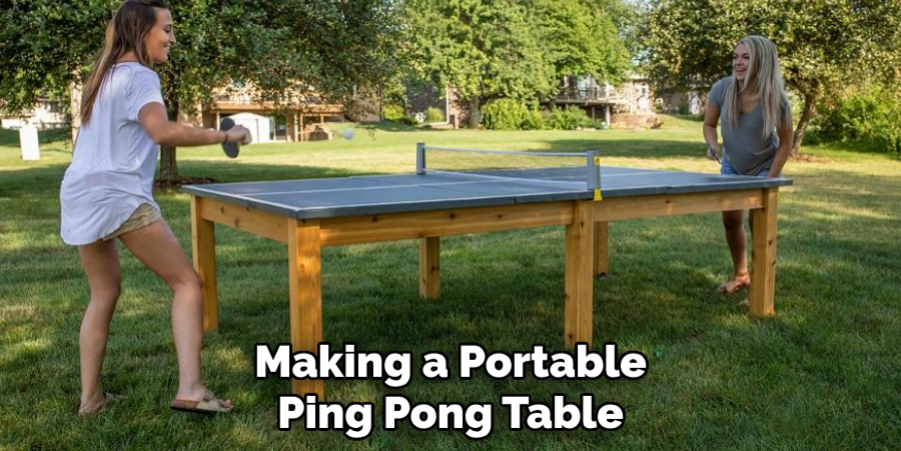

7. Making a Portable Ping Pong Table

A portable ping pong table is ideal for those who need a lightweight and movable setup. Use a lightweight plywood or MDF board and attach foldable aluminum legs to ensure easy transportation. Divide the tabletop into two sections for easier handling. Attach a compact, retractable net that can be clipped on when needed. A handle or wheels can be added for added mobility.

8. Constructing a Multi-Purpose Table

If you want a ping pong table that doubles as a dining or work table, design a multi-purpose table with a removable or reversible top. One side can feature a finished wood or glass surface for everyday use, while the other side is coated for ping pong play. Install sturdy hinges or detachable clamps to make flipping or removing the surface easy.

9. Using PVC Pipes for a Budget-Friendly Frame

For those on a budget, constructing the table frame using PVC pipes is a cost-effective alternative to wood or metal. Use thick, high-quality PVC pipes and connectors to assemble a strong base, ensuring the height meets regulation standards. Secure the tabletop using clamps or screws. This setup is lightweight, making it easy to move or disassemble when not in use.

10. Enhancing Playability with a Proper Finish

Regardless of the materials used, the final finish of the table is crucial for optimal gameplay. Use a dark green or blue paint for the playing surface, applying multiple layers for durability. Add a clear coat for extra protection. Carefully mark and paint white boundary lines to standard specifications. Ensuring the surface is smooth and resistant to warping will help maintain consistent ball bounce.

Troubleshooting Common Issues

Building or maintaining a ping pong table can sometimes present challenges. Below are some common issues and their solutions to help ensure the table remains in excellent condition and provides consistent gameplay.

Uneven Surface

Over time, the playing surface may develop uneven areas that affect ball bounce. This can be caused by warping of wood or improper assembly. To resolve this, check the frame and tighten all screws or brackets. If the surface itself is warped, consider replacing or reinforcing it with additional support.

Instability

A wobbly or unstable table can disrupt gameplay. Ensure that all legs are firmly attached and that adjustable feet, if installed, are properly aligned to balance the table. If the table is situated on an uneven floor, use shims or leg levelers to stabilize it.

Peeling or Chipping Paint

Frequent use can result in paint peeling or chipping, especially around the edges of the table. To fix this, sand the affected areas lightly and apply a fresh coat of paint, followed by a clear protective finish to prevent further damage.

Conclusion

Building a ping pong table can be a fun and fulfilling project, providing a customizable and cost-effective alternative to store-bought options. Whether you choose a simple plywood build, a foldable design, or an advanced concrete structure, selecting the right materials and construction techniques will ensure a long-lasting and enjoyable playing experience.

Thanks for reading our blog post on how to make a ping pong table! We hope you found it helpful and informative.

Huston Douthit is a distinguished figure in the world of furniture design, with a decade of expertise creating innovative and sustainable furniture solutions. His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques, fostering designs that are both practical and environmentally conscious. As the author of Fruniturix, Huston delves into the art and science of furniture-making, inspiring artisans and industry professionals alike.

Education

- RMIT University (Melbourne, Australia)

Associate Degree in Design (Furniture)- Focus on sustainable design, industry-driven projects, and practical craftsmanship.

- Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

- Nottingham Trent University (United Kingdom)

Bachelor’s in Furniture and Product Design (Honors)- Specialized in product design with a focus on blending creativity with production techniques.

- Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In Fruniturix, Huston shares his insights on furniture design processes, materials, and strategies for efficient production. His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.